01 02 03 04 05

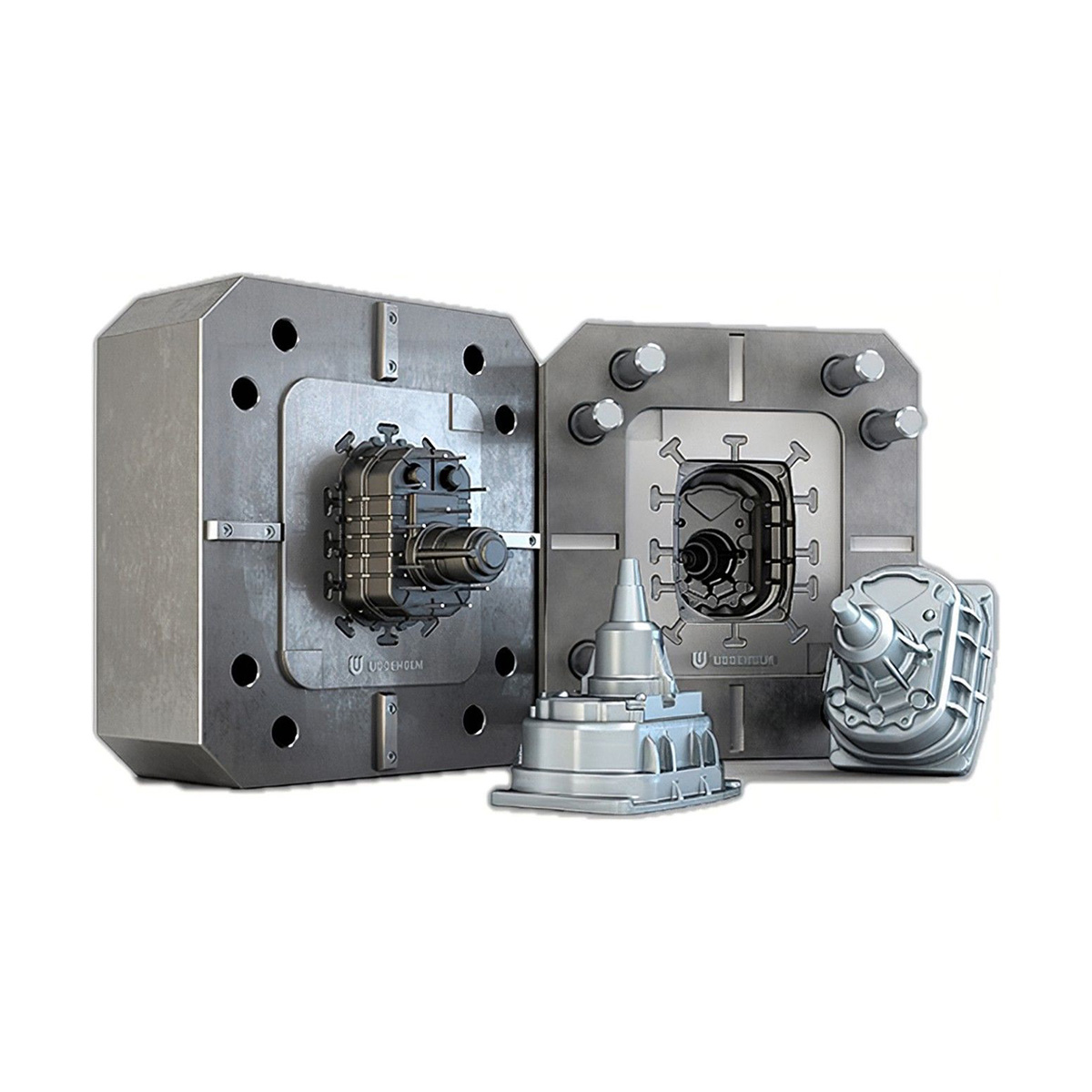

Custom Die Casting Mold Tooling kayayyakin - mutu simintin gyare-gyaren masana'anta

Cikakken Bayani

Tsarin kayan aikin simintin gyare-gyaren mutuƙar ya ƙunshi matakai da yawa:

● Zane: Mataki na farko shine zayyana kayan aikin ƙira bisa ga siffar da ake so da ƙayyadaddun ɓangaren. Wannan ya haɗa da ƙirƙirar ƙirar 3D na ɓangaren da kuma zayyana kogon ƙura, masu gudu, huluna, da tashoshi masu sanyaya.

Zaɓin kayan aiki: Mataki na gaba shine zaɓi kayan da ya dace don kayan aikin ƙera. Ya kamata kayan ya kasance yana da kyakykyawan halayen zafin jiki, juriya, da kwanciyar hankali mai girma don jure yanayin zafi da matsi da ke tattare da tsarin simintin mutuwa. Abubuwan da aka saba amfani da su don kayan aikin ƙira sun haɗa da ƙarfe kayan aiki, H13, da P20.

● Ƙimar ƙira: Da zarar an kammala zane da zaɓin kayan aiki, ana yin amfani da kayan aiki na kayan aiki ta hanyar amfani da matakai daban-daban kamar milling, hakowa, niƙa, da kuma EDM (Machining Electrical Discharge Machining). Yawanci ana yin gyare-gyare a cikin rabi biyu, rami da ainihin, waɗanda aka ɗora a kan na'ura mai mutuwa.

● Magani a saman: Bayan an ƙera kayan aikin gyaggyarawa, ana iya yin jiyya a saman kamar goge-goge, rubutu, ko sutura don inganta bayyanar da aikin sashin.

● Taruwa da gwaji: An haɗa kayan aikin ƙirar, kuma ana yin gwaji sosai don tabbatar da cewa yana aiki daidai kuma yana samar da sassa masu inganci. Wannan ya haɗa da tabbatar da ma'auni, nazarin kwararar narkakkar karfe, da inganta tsarin sanyaya.

Ƙirƙirar: Da zarar kayan aikin ƙirar ya shirya, ana iya amfani da shi a cikin tsarin simintin simintin don samar da sassan ƙarfe. Ana ɗora ƙirar a kan injin ɗin simintin simintin gyare-gyare, kuma ana yin allurar narkakken ƙarfe a ƙarƙashin babban matsi a cikin kogon ƙura. Bayan ƙarfafawa, ana buɗe ƙirar, kuma an fitar da ɓangaren simintin.

Yana da mahimmanci don kulawa da kyau da kuma gyara kayan aiki na kayan aiki don tabbatar da tsawon lokaci da aiki mafi kyau. Dole ne a gudanar da tsaftacewa na yau da kullun, lubrication, da dubawa don hana lahani, tsawaita tsawon rayuwar ƙirar, da kiyaye daidaiton ingancin sashi.

A ƙarshe, kayan aikin simintin simintin gyare-gyare shine muhimmin al'amari na aikin simintin mutuwa. Ƙirar da ta dace, zaɓin kayan aiki, masana'antu, da kuma kula da kayan aiki na kayan aiki suna da mahimmanci don samar da sassan ƙarfe masu inganci da inganci da tsada.

Siffofin

Lokacin yin simintin simintin gyare-gyare, kuna buƙatar kula da waɗannan abubuwan:

Zaɓin Abu: Zaɓi kayan da ya dace dangane da siffa da girman ɓangaren. Siffofin daban-daban da girma dabam na iya buƙatar kayan daban-daban. A lokaci guda, ya kamata a yi la'akari da girman tsari da bukatun samarwa. Don manyan girma da sassa masu inganci, kayan da ke da ƙarfi da ƙarfi ya kamata a zaɓa. A lokaci guda, dole ne a yi la'akari da ƙimar farashi da samarwa, kuma kayan da ke da tattalin arziki da araha na iya tabbatar da inganci.

Tsarin ƙira: Tsarin ƙirar ya kamata ya dace da buƙatun sassa kuma ya dace da aikin aiki da buƙatun bayyanar samfur. Lokacin zayyana, ya kamata a ba da hankali ga gujewa ko rage sasanninta masu kaifi da kusurwoyi matattu a cikin ƙirar don sauƙaƙe kwararar kayan aiki da gyare-gyare. A lokaci guda, ya kamata a yi la'akari da tsarin sanyaya da kuma samun iska na mold don tabbatar da ingancin sassan da aka ƙera.

Fasahar sarrafawa: Lokacin yin gyare-gyare, kula da zabar fasahar sarrafawa mai dacewa, ciki har da kayan aiki na kayan aiki na CNC, EDM, niƙa, da dai sauransu A lokacin aiki, ya kamata a biya hankali don kiyaye daidaito da ingancin ƙirar ƙira don kauce wa lalata ƙirar.

Maganin zafi: Don wasu ƙira, ana buƙatar maganin zafi don inganta taurin da juriya na kayan. A lokacin aikin maganin zafi, dole ne a sarrafa zafin jiki da lokaci don tabbatar da tasirin maganin zafi.

Haɗawa da gyara kurakurai: Haɗa ɓangarorin da aka sarrafa kuma a cire su. A lokacin da ake yin kuskure, kula da hankali don bincika ko ƙaddamarwa da shigarwa na mold daidai ne, kuma ko aiki da gyare-gyaren ƙirar ƙirar sun dace da bukatun.

Kulawa da Kulawa: Ya kamata a kiyaye da kuma kula da ƙirar a kai a kai yayin amfani, gami da tsaftace tsararren, shafa mai, da kuma duba lalacewa da lalacewar ƙirar. Gyara da maye gurbin lalacewa a cikin lokaci don tabbatar da rayuwa da kwanciyar hankali na mold.

Lokacin yin gyare-gyaren simintin gyare-gyaren mutuwa, kuna buƙatar kula da abubuwan da ke sama don tabbatar da inganci da ingancin samfurin. Zaɓuɓɓuka da tsarin samar da gyare-gyare suna da mahimmanci kuma suna taka muhimmiyar rawa wajen samar da masana'antu na zamani.

Aikace-aikace

Ma'auni

| Kayan abu | Halayen kayan abu |

| Alloy karfe | Wadannan karafa suna da halaye na tsayin daka, juriya mai girma, ƙarfin ƙarfi, da ƙarfi mai ƙarfi, wanda zai iya biyan buƙatun ƙirar ƙira mai ƙima da inganci mai inganci. |

| jan karfe gami | Copper gami babban ingancin mutu-simintin gyare-gyaren abu ne tare da kyakyawan yanayin zafi mai kyau da ɗawainiya, wanda ya dace da kera manyan sifofi masu rikitarwa masu simintin simintin gyare-gyare. |

| Aluminum gami | Aluminum gami yana da nauyi mai nauyi, babban ƙarfi, da juriya mai kyau na lalata, yana mai da shi dacewa da kera ƙananan simintin simintin gyare-gyaren ƙanana da matsakaici. |

| magnesium gami | Magnesium alloy wani abu ne mai sauƙi, mai ƙarfi, kuma abu mai jure lalata wanda ya dace da kera manyan ƙera kayan simintin simintin gyare-gyare. |

Me Yasa Zabe Mu

1. Sabis na Tsayawa ɗaya don adana lokaci.

2. Masana'antu a cikin rabo don adana farashi.

3. Keyence, ISO9001 da kuma tabbatar da inganci.

4. Ƙungiyar Farfesa da Ƙarfi Mai Ƙarfi don tabbatar da bayarwa.

Gida

Gida