01 02 ib 03 04 ib 05

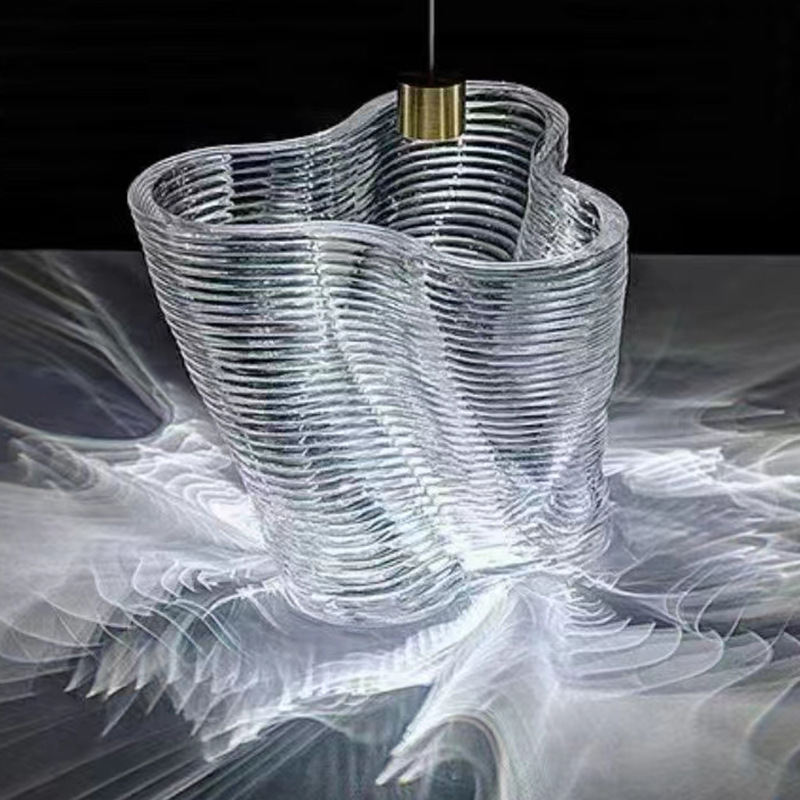

Thaum tshav kub kub Sink Tuag casting Hlau qhov chaw

Product Detail

Cov txheej txheem ntawm kev tsim cov hlau tuag-casting muaj xws li cov kauj ruam hauv qab no:

Tsim cov casting: Txiav txim siab cov duab, qhov loj me, thiab cov khoom siv ntawm cov khoom raws li cov khoom xav tau thiab tsim.

Ua cov pwm: Tsim cov pwm siv rau kev tuag-casting raws li tus qauv tsim. Cov pwm feem ntau muaj ob ntu, sab sauv thiab qis tuag, nrog cov kab noj hniav hauv qhov sib piv rau qhov xav tau ib feem.

Npaj cov ntaub ntawv: Xaiv cov khoom siv hlau lossis hlau thiab ua kom sov kom yaj raws li qhov sib piv.

Cov txheej txheem tuag-casting: Txhaj cov hlau molten rau hauv pwm thiab siv lub zog siab kom txias thiab ua kom khov rau hauv ib lub sijhawm.

Demolding thiab tom qab ua tiav: Tom qab cov hlau tuag-cam khwb cia yog txias, qhib lub pwm thiab tshem tawm qhov ua tiav. Ua kev kho saum npoo, tshem tawm cov npoo ntau dhau, thiab luas raws li xav tau.

Tuag-cam khwb cia hlau qhov chaw muaj zoo heev lub cev thiab txhua yam khoom thiab yog dav siv nyob rau hauv kev lag luam xws li tsheb, machinery, electronics, thiab aerospace. Los ntawm cov txheej txheem tuag-casting, ntau qhov ntau ntawm cov hlau tuaj yeem tsim tau zoo thiab raug raws li qhov xav tau ntawm kev lag luam sib txawv.

Daim ntawv thov

Tuag-cam khwb cia hlau qhov chaw muaj zoo heev lub cev thiab txhua yam khoom thiab yog dav siv nyob rau hauv kev lag luam xws li tsheb, machinery, electronics, thiab aerospace. Los ntawm cov txheej txheem tuag-casting, cov khoom siv hlau loj tuaj yeem tsim tau zoo thiab raug raws li qhov xav tau ntawm kev lag luam sib txawv.

Tsis muaj

| Tus lej | qhov project | tsis muaj |

| 1 | Khoom npe | Zinc alloy tuag casting, aluminium alloy tuag casting |

| 2 | Khoom siv | Zinc aluminium, aluminium alloy |

| 3 | Pwm Khoom | H13 |

| 4 | Kev kos duab | IGES, STP, PDF, AutoCad |

| 5 | Kev piav qhia | Kev pabcuam ib-nres los muab cov qauv tsim, pwm kev txhim kho thiab kev ua pwm. Kev tsim khoom thiab kev tawm tswv yim. khoom tiav, sib dhos thiab ntim, thiab lwm yam |

Tom qab kev kho mob ntawm tuag casting

Electroplating

Electroplating thiab txheej: Siv cov hlau los yog tsis yog xim hlau nyias zaj duab xis rau ntawm qhov chaw ntawm qhov casting los ntawm electrochemical txoj kev los txhim kho nws cov khoom tiv thaiv, kho kom zoo nkauj, thiab corrosion kuj.

Txheej: siv tshuaj tsuag,

Txau painting

Yuav luag txhua cov ntaub ntawv tuaj yeem siv tau, qhov ceev yog nyob ntawm qhov loj thiab qib ntawm automation, lub sij hawm ziab yog tsawg kawg yog ib nrab teev, cov khoom nto xim du thiab zoo li qub.

Polishing

Cov cuab yeej siv tau yooj yim, cov khoom siv tsawg dua, tus nqi qis dua, thiab qhov nrawm nrawm dua, yog li cov hlau saum npoo tuaj yeem tau txais qhov tsis zoo li daim iav zoo li luster, thiab tib lub sijhawm, nws tuaj yeem tshem tawm qhov tsis xws luag.

Kev kho cua sov

Hloov cov hlau nplaum microstructure thiab cov khoom los ntawm cov txheej txheem xws li cua sov thiab cua txias, txhim kho cov khoom siv zog, hardness, thiab corrosion kuj.

Machining: Siv cov txheej txheem machining thiab kev kho cua sov rau castings thiaj li ua tiav qhov ntev thiab cov duab.

Ntxuav

Tshem cov roj stains, hlau chips, thiab lwm yam impurities los ntawm qhov chaw ntawm castings kom huv si thiab smoothness.

Cov txheej txheem tom qab casting txheej txheem tuaj yeem ua tau.

Kev soj ntsuam zoo

1. Kev tshuaj ntsuam xyuas: Tshawb xyuas cov khoom siv raw, cov khoom siv lossis cov khoom ua tiav uas muab los ntawm cov neeg muag khoom kom ntseeg tau tias lawv cov khoom ua tau raws li daim ntawv cog lus yuav khoom thiab cov kev qhia tshwj xeeb.

2. Kev soj ntsuam cov txheej txheem: Saib xyuas thiab tshuaj xyuas txhua tus txheej txheem hauv cov txheej txheem tsim khoom kom sai li sai tau tshawb pom thiab kho cov khoom tsis tsim nyog los tiv thaiv lawv los ntawm kev ntws mus rau hauv cov txheej txheem tom ntej lossis cov khoom lag luam tiav.

3. Kev tshuaj xyuas cov khoom tiav: Lub chaw soj ntsuam zoo ntawm ABBYLEE yuav siv cov tshuab kuaj kev tshaj lij: Keyence, ua cov khoom kuaj xyuas meej. Kev tshuaj xyuas tag nrho ntawm cov khoom tiav, suav nrog cov tsos, qhov loj me, kev ua haujlwm, kev ua haujlwm, thiab lwm yam, kom ntseeg tau tias lawv cov khoom ua tau raws li lub Hoobkas thiab cov neeg siv khoom xav tau.

4. Kev tshuaj xyuas lub Hoobkas: Kev kuaj xyuas tag nrho lossis kev tshuaj xyuas tag nrho ntawm cov khoom tiav uas yuav tawm hauv lub hoobkas los xyuas seb lawv cov khoom puas ua tau raws li qhov yuav tsum tau ua ntawm daim ntawv cog lus lossis kev txiav txim.

Ntim

1. Hnab ntim khoom: Siv cov yeeb yaj kiab tiv thaiv kom ntim cov khoom kom nruj kom tsis txhob muaj kev sib tsoo thiab kev sib txhuam. Foob thiab xyuas kom muaj kev ncaj ncees.

2. Ntim: Muab cov khoom ntim ntim rau hauv thawv rau hauv ib txoj kev, kaw lub thawv thiab sau npe nrog lub npe, specifications, kom muaj nuj nqis, batch naj npawb thiab lwm yam ntaub ntawv ntawm cov khoom.

3. Warehousing: Thauj cov khoom ntim rau hauv lub warehouse rau kev tso npe rau hauv warehousing thiab classified cia, tos rau cov khoom xa tuaj.

Tsev

Tsev