01 02 03 04 05

Lihlahisoa tsa Custom Die Casting Mold Tooling - tlhahiso ea hlobo ea die casting

Lintlha tsa Sehlahisoa

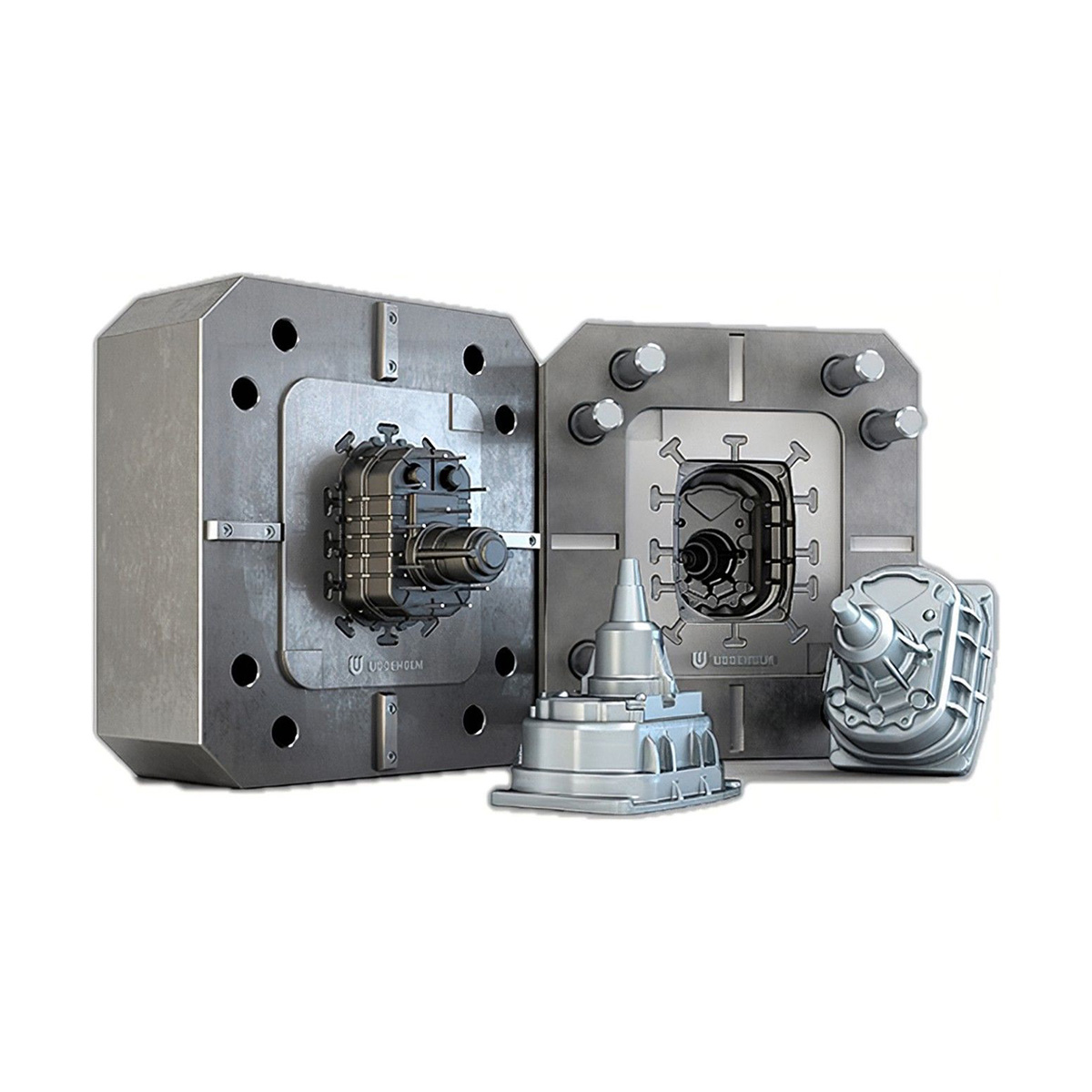

Mokhoa oa ho sebelisa hlobo ea die casting mold hangata o kenyelletsa mehato e mengata:

● Moralo: Mohato oa pele ke ho etsa moralo oa lisebelisoa tsa hlobo ho latela sebopeho se lakatsehang le litlhaloso tsa karolo eo. Sena se kenyelletsa ho theha mohlala oa 3D oa karolo le ho rala sebaka sa hlobo, limathi, li-vents le likanale tse pholileng.

● Khetho ea thepa: Mohato o latelang ke ho khetha thepa e loketseng bakeng sa lisebelisoa tsa hlobo. Thepa e lokela ho ba le conductivity e ntle ea mocheso, ho hanyetsa ho roala, le botsitso ba dimensional ho mamella mocheso o phahameng le likhatello tse amehang ts'ebetsong ea ho lahla. Lisebelisoa tse tloaelehileng tse sebelisoang bakeng sa lisebelisoa tsa hlobo li kenyelletsa tšepe ea sesebelisoa, H13, le P20.

● Ho etsa hlobo: Hang ha moralo le khetho ea thepa e phethoa, sesebelisoa sa hlobo se etsoa ho sebelisoa mekhoa e sa tšoaneng ea machining e kang ho sila, ho phunya, ho sila, le EDM (Motlakase oa Ts'ebetso ea Motlakase). Hangata hlobo e entsoe ka lihalofo tse peli, sekoti le mokokotlo, tse behiloeng mochine oa ho lahla.

● Phekolo ea holim'a metsi: Ka mor'a hore mochini oa hlobo o etsoe ka mochine, o ka 'na oa phekoloa ka holim'a metsi a kang ho bentša, ho kenya mongolo, kapa ho roala ho ntlafatsa ponahalo le ts'ebetso ea karolo eo.

● Ho kopanya le ho hlahloba: Lisebelisoa tsa hlobo li bokelloa, 'me ho etsoa tlhahlobo e feletseng ho netefatsa hore e sebetsa ka nepo le ho hlahisa likarolo tsa boleng bo phahameng. Sena se kenyeletsa ho netefatsa boholo, ho hlahloba ho phalla ha tšepe e qhibilihisitsoeng, le ho ntlafatsa tsamaiso ea ho pholisa.

Tlhahiso: Hang ha sesebelisoa sa hlobo se se se loketse, se ka sebelisoa ts'ebetsong ea ho lahla ho hlahisa likarolo tsa tšepe. Hlobo e kenngoa mochining oa die casting, 'me tšepe e qhibilihisitsoeng e kenngoa tlas'a khatello e phahameng ka har'a mokoti oa hlobo. Kamora ho tiisa, hlobo ea buloa, 'me karolo e lahliloeng e ntšoa.

Ho bohlokoa ho boloka le ho lokisa lisebelisoa tsa hlobo ho netefatsa bophelo ba eona bo bolelele le ts'ebetso e nepahetseng. Ho hloekisoa khafetsa, ho tlotsa le ho hlahlojoa ho lokela ho etsoa ho thibela mefokolo, ho lelefatsa bophelo ba hlobo, le ho boloka boleng ba karolo e tšoanang.

Qetellong, lisebelisoa tsa hlobo ea die casting ke karolo ea bohlokoa ea mokhoa oa ho lahla lefu. Moqapi o nepahetseng, khetho ea thepa, tlhahiso le tlhokomelo ea lithulusi tsa hlobo ke tsa bohlokoa bakeng sa ho hlahisa likarolo tsa tšepe tsa boleng bo phahameng ka mokhoa o atlehileng le o theko e tlaase.

Likaroloana

Ha u etsa hlobo ea die-casting, u lokela ho ela hloko lintlha tse latelang:

Khetho ea Boitsebiso: Khetha thepa e loketseng ho latela sebōpeho le boholo ba karolo. Libopeho le boholo bo fapaneng li ka hloka lisebelisoa tse fapaneng. Ka nako e ts'oanang, boholo ba batch le litlhoko tsa tlhahiso li lokela ho nkoa. Bakeng sa likarolo tse kholo le tsa boleng bo phahameng, lisebelisoa tse nang le matla le boima bo phahameng li lokela ho khethoa. Ka nako e ts'oanang, litšenyehelo le katleho ea tlhahiso li tlameha ho nahanoa, 'me lisebelisoa tse nang le chelete e ngata le tse theko e tlaase li ka netefatsa boleng.

Moqapi oa hlobo: Moqapi oa hlobo o lokela ho finyella litlhoko tsa likarolo le ho finyella litlhoko tsa ts'ebetso le ponahalo ea sehlahisoa. Ha ho etsoa moralo, tlhokomelo e lokela ho lefshoa ho qoba kapa ho fokotsa likhutlo tse bohale le likhutlo tse shoeleng ka har'a hlobo ho thusa ho phalla ha thepa le ho bopa. Ka nako e ts'oanang, mokhoa oa ho pholisa le oa moea oa hlobo o lokela ho nkoa ho netefatsa boleng ba likarolo tse bōpiloeng.

Theknoloji ea ho sebetsa: Ha u etsa liforomo, ela hloko ho khetha theknoloji e nepahetseng ea ho sebetsa, ho kenyelletsa le lisebelisoa tsa mochine oa CNC, EDM, ho sila, joalo-joalo Nakong ea ts'ebetso, tlhokomelo e lokela ho lefshoa ho boloka ho nepahala le boleng ba holim'a hlobo ho qoba ho senya hlobo.

Kalafo ea mocheso: Bakeng sa liforomo tse ling, phekolo ea mocheso e hlokahalang ho ntlafatsa ho thatafala le ho apara ho hanyetsa ha thepa. Nakong ea ts'ebetso ea phekolo ea mocheso, mocheso le nako li tlameha ho laoloa ho netefatsa phello ea phekolo ea mocheso.

Ho kopanya le ho lokisa liphoso: Kopanya likarolo tse lokiselitsoeng le ho li lokisa. Ha u lokisa liphoso, ela hloko ho hlahloba hore na ho qhaqhoa le ho kenya hlobo ho nepahetse, le hore na ts'ebetso le phello ea ho bopa ea hlobo e finyella litlhoko.

Tlhokomelo le tlhokomelo: Hlobo e lokela ho hlokomeloa le ho hlokomeloa kamehla nakong ea tšebeliso, ho kopanyelletsa le ho hloekisa hlobo, ho tlotsa hlobo, le ho hlahloba ho senyeha le ho senyeha ha hlobo. Lokisa le ho fetola likarolo tse senyehileng ka nako ho netefatsa bophelo le botsitso ba hlobo.

Ha u etsa li-molds tsa die-casting, u lokela ho ela hloko lintlha tse ka holimo ho netefatsa boleng le katleho ea tlhahiso ea hlobo. Mokhoa oa ho khetha le ho hlahisa hlobo ke oa bohlokoa haholo 'me o phetha karolo ea bohlokoa tlhahisong ea kajeno ea indasteri.

Kopo

Mekhahlelo

| Lintho tse bonahalang | Litšobotsi tsa lintho tse bonahalang |

| Tšepe ea motsoako | Litšepe tsena li na le litšoaneleho tsa boima bo phahameng, khanyetso e phahameng ea ho apara, matla a phahameng, le boima bo phahameng, tse ka finyellang litlhoko tsa ho etsoa ha hlobo e phahameng ka ho fetisisa le ea boleng bo phahameng. |

| motsoako oa koporo | Copper alloy ke boleng ba boleng bo phahameng ba ho lahla hlobo e nang le conductivity e ntle ea mocheso le conductivity, e loketseng ho etsa liforomo tse kholo le tse rarahaneng tsa sebopeho sa die-casting. |

| Motsoako oa aluminium | Aluminium alloy e na le boima bo bobebe, matla a phahameng, 'me e hanyetsa ho bola, e etsa hore e lokele ho etsa liforomo tse nyane le tse mahareng tse etsang li-die-casting. |

| motsoako oa magnesium | Magnesium alloy ke thepa e bobebe, e matla haholo ebile e hana ho bola e loketseng ho etsa liforomo tse sebetsang hantle haholo. |

Ke Hobane'ng ha U Re Khetha

1. Tshebeletso ya One-Stop ho boloka nako.

2. Lifeme ka kabelo ho boloka litšenyehelo.

3. Keyence, ISO9001 le ho netefatsa boleng.

4. Sehlopha sa Moprofesa le Mokhoa o Matla oa ho netefatsa phano.

Lehae

Lehae