BLOG- How to Choose Material for CNC machining

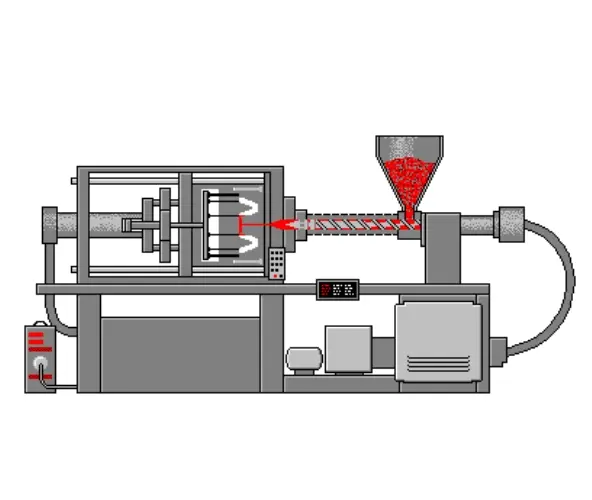

CNC machining, full name(Computerized Numerical Control)

CNC machining is a rapid manufacturing process that converts 3D designs into products by selectively cutting material.

The Advantage of CNC machining :

1.One-Stop service with Higher convenience, The number of tooling is greatly reduced, complex tooling is no longer required for processing parts with complex shapes.

2, CNC machining can ensure more stable machining quality, Higher precision of processing and the repeatability.

3, Quicker speed to shorter the lead time of products.

Because of these advantages, it's very common in prototyping and customizing products.

For CNC metal machining, the used material include Aluminum, Stainless Steel, and most Alloy. Here’s The list:

Aluminum Alloy | AL6061, AL5052 AL7075, etc |

Stainless Steel | SST304, SST316, SST316L, 17-4PH, etc |

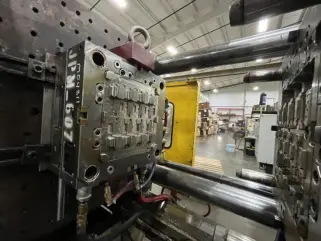

Alloy | Spring Steel, Mold Steel, 40Cr, etc |

Steel | |

Copper or Brass Alloy | Brass-H59, Brass-H62, Copper-T2, etc |

Other Alloy | Ti Alloy- TC4,Mg Alloy, etc |

Most common metal material we used are Aluminum and Stainless Steel.

The price of Aluminum is better then SST, and itself is lighter and more resistant to corrosion. Aluminum support anodized, which mean the surface of aluminum products would be more clean and smooth.

The stainless steel have a good surface, and it won’t be easily rusted.The surface of stainless steel is relatively flat, with higher strength, and better resistance to pressure and impact.

The Choice of CNC machining material mostly depends on your requirements of parts: hardness, surface finish,heat resistance, weight, price, and the applications.

Based on these requirments, our technical team could also help you by suggesting the best material we can offer.

Choosing the right material for CNC machining is crucial for the success of a project. The selection process involves considering the functional requirements of the parts, such as strength, wear resistance, and corrosion resistance. Additionally, the machinability of the material is an important factor to consider, as some materials are easier to machine than others. Cost is also a significant consideration, encompassing both the material cost and the machining cost. By carefully evaluating these factors, it is possible to choose the most suitable material that meets the project requirements while ensuring cost-effectiveness and high-quality end products.