0102030405

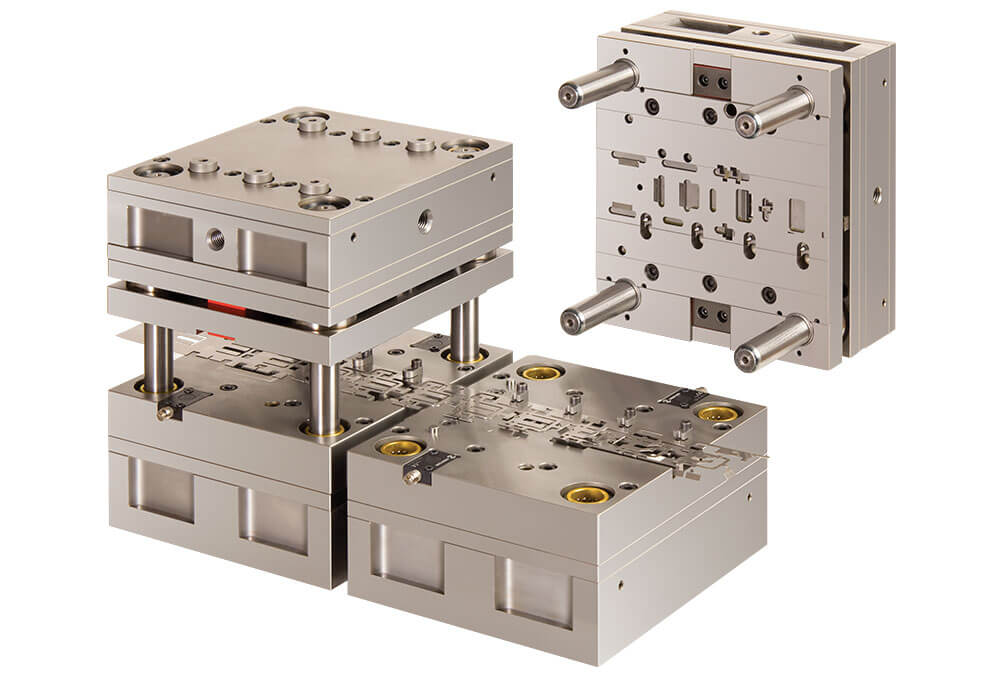

The composition mold cavity and application of injection mould

2024-04-18 17:38:56

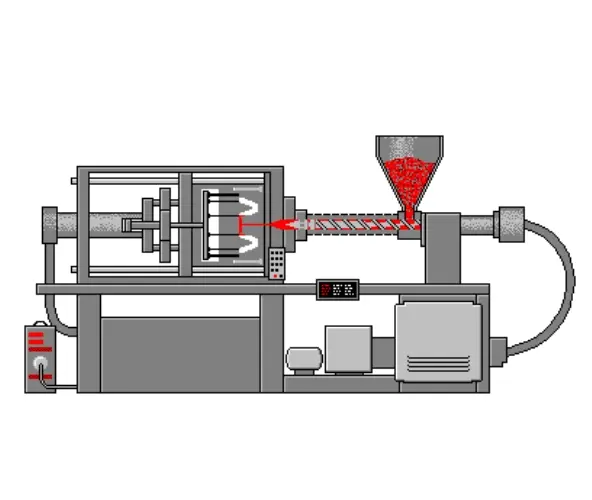

An injection mold is a tool for producing plastic products; it is also a tool that gives plastic products complete structure and precise dimensions. Because the main production method is to inject high-temperature melted plastic into the mold through high pressure and mechanical drive, it is also called a plastic injection mold.

Component:

1.Gating system refers to the plastic flow channel in the mold from the nozzle of the injection molding machine to the cavity. Ordinary pouring systems are composed of main channels, runner channels, gates, cold material holes, etc.

2.Lateral parting and core pulling mechanism.

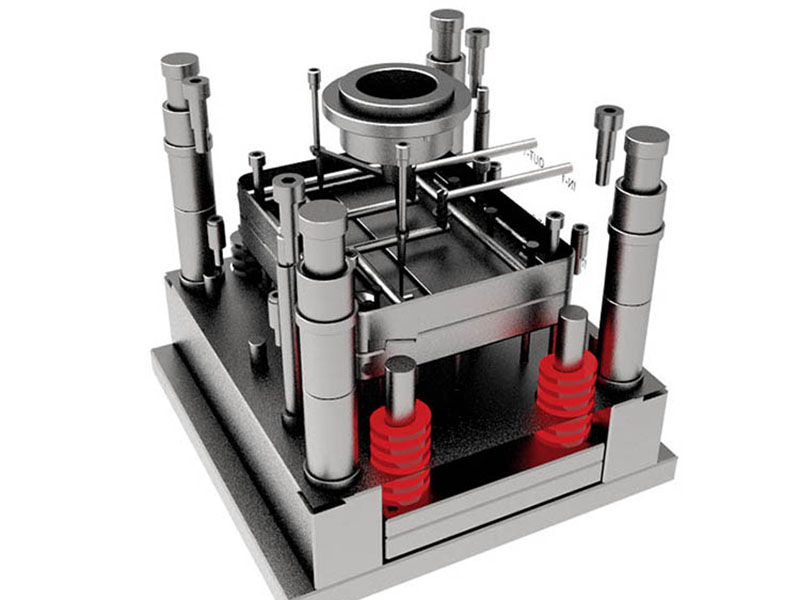

3.The guide mechanism in the plastic mold mainly has the functions of positioning, guiding, and bearing a certain side pressure to ensure accurate closing of the moving and fixed molds. The mold clamping guide mechanism consists of guide posts, guide sleeves or guide holes (directly opened on the template), positioning cones, etc.

4. The ejection device mainly plays the role of ejecting the workpiece from the mold, and is composed of an ejector rod or a ejector tube or a push plate, an ejector plate, an ejector fixed plate, a reset rod, and a pull rod.

5. Cooling and heating system.

6. Exhaust system.

7. Molded parts refer to the parts that constitute the mold cavity. Mainly including: punch mold, concave mold, core, forming rod, forming ring and inserts and other parts.

Classification:

Injection molds are divided into thermosetting plastic molds and thermoplastic plastic molds according to molding characteristics; according to the molding process, they are divided into stamping mould tooling, transfer mould, blow mould, cast mould, thermoforming mould, and hot pressing mould, injection mould, etc.

Material:

The material of the mold directly affects the cooling effect. Commonly used mold materials include P20 steel, H13 steel, P6 steel, S7 steel, beryllium copper alloy, aluminum, 420 stainless steel, and 414 stainless steel.

Cavity:

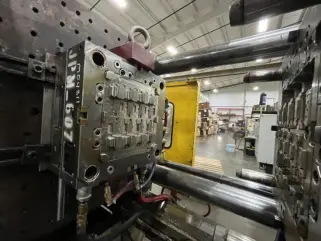

The mold cavity is a space with the same shape as the molded product left in the mold to accommodate the molten plastic and form the product after pressure holding and cooling. This space is also called the mold cavity. Usually smaller finished products are designed as "multi-cavity molds" for the sake of economy and efficiency. For example, a mold has several identical or similar film cavities for rapid production.

Draft angle:

Typical standard draft angle are within 1 to 2 degrees (1/30 to 1/60). The depth is about 1.5 degrees for 50 to 100 mm, and about 1 degree for 100 mm. The ribs should not be less than 0.5 degrees and the thickness should not be less than 1 mm to facilitate mold production and increase the life of the mold.

When encountering the need for texture, it is recommended that the angle must be larger than the normal situation. The angle given by it should preferably be more than 2 degrees, but the angle should not be greater than 5 degrees.

Basic style:

The two-plate mold is the most commonly used mold type and has the advantages of low cost, simple structure and short molding cycle.

The runner system of the three-plate mold is located on the material plate. When the mold is opened, the material plate ejects the waste material in the runner and bushing. In the three-plate mold, the runner and the finished product will be ejected separately.

Common types:

Stamping mould tooling is a special process equipment used to process materials into parts in cold stamping processing. It is called cold stamping die. Stamping is a pressure processing method that uses a mold installed on a press to apply pressure to the material at room temperature to cause separation or plastic deformation to obtain the required parts.