0102030405

Custom CNC parts products - CNC machining prototype manufacturing

Product Detail

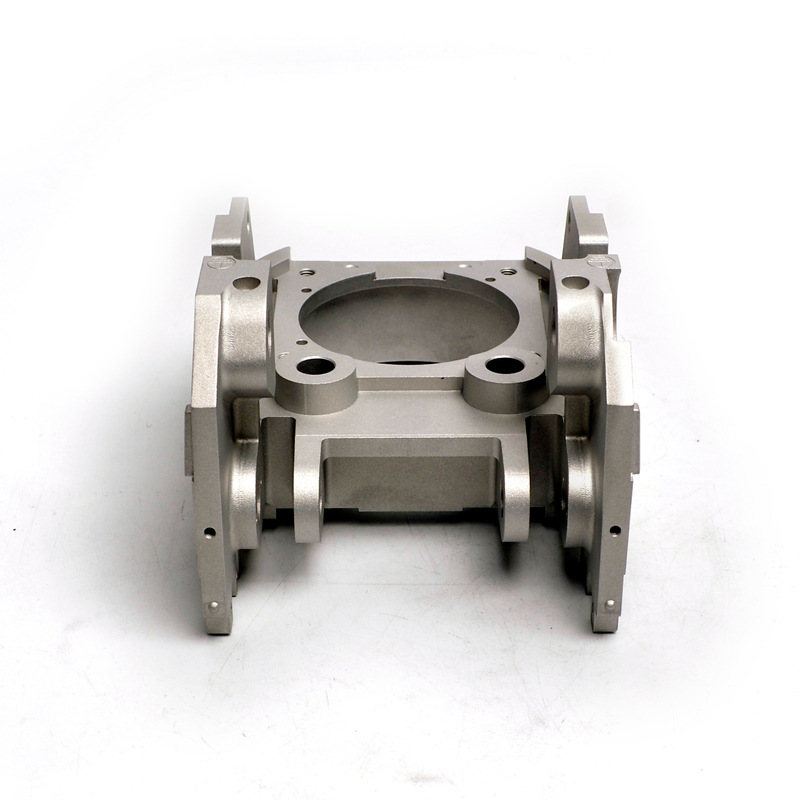

Computer numerically controlled lathe is the most widely used CNC machine tool in China. CNC machine tools are mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology as one of the electromechanical integration products. It is a working machine with high precision, high efficiency, high automation and high flexibility, stable and reliable processing quality in mechanical manufacturing equipment.

The manufacture of CNC parts products mainly uses aluminum alloy, stainless steel, low carbon steel, brass, titanium, magnesium, PA, PC, ABS, PMMA, PTFE, EP and other materials, can be manufactured products include aircraft parts, automotive parts, medical equipment, consumer goods, electronic hardware, mechanical equipment, transparent pipes, plastic molds, bearings, gears and so on.

Features

1. Greatly reduce the number of tooling, processing complex shape parts do not need complex tooling. If you want to change the shape and size of the parts, you only need to modify the parts processing program, which is suitable for new product development and modification.

2. Stable processing quality, high processing accuracy, high repetition accuracy, suitable for the processing requirements of aircraft.

3. The production efficiency is higher in the case of multi-variety and small-batch production, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the best cutting amount.

4. It can process complex surfaces that are difficult to be processed by conventional methods, and can even process some unobservable processing parts.

Application

Design drawings can be supplied for mass production by our factory. The material can be selected, and the style and color of CNC parts products are not restricted. Any custom product you need, we can produce.

Parameters

| Material | Products suitable for manufacturing | Material characteristics |

| aluminium alloy | Aircraft components, automotive parts, bicycle frames, food containers | Aluminum alloy has excellent strength to weight ratio, high thermal conductivity and conductivity, as well as natural corrosion protection. They are easy to process and have low batch costs, so they are usually the most economical choice for manufacturing customized metal parts and prototypes. |

| Stainless steel | Surgical equipment, electronic hardware | Stainless steel is highly favored for its strength and corrosion resistance, making it a widely used material that is relatively lightweight and durable, expanding its application in various industries. |

| mild steel | Machine parts, fixtures, fixtures | Low carbon steel has low cost, good mechanical properties, good machinability, and good weldability. |

| brass | Medical equipment, consumer goods, electronic hardware, accessories | Brass is widely regarded as one of the simplest and most cost-effective materials for precision machining services. It has good machinability and excellent conductivity, making it very suitable for applications that require low friction. |

| titanium | Medical implants, aircraft components, jewelry | Titanium is heat-resistant and corrosion-resistant, making it a viable choice for many industrial applications. |

| Well | Bearings, gears, cams, guides, tire cords | PA has high strength, wear resistance, fatigue resistance, oil resistance, water resistance, mold resistance, non-toxic, and high water absorption. |

| PC | Machined gears, racks, worm gears, worms, bulletproof glass, capacitors | PC has good comprehensive performance, good impact toughness, good dimensional stability, colorless and transparent, low water absorption, good heat resistance, creep resistance, and electrical insulation. |

| ABS | Gears, impellers, mechanical equipment casings, machined structural components | ABS has good comprehensive performance, impact resistance, good dimensional stability, easy electroplating, easy mechanical processing, light weight, and opacity. |

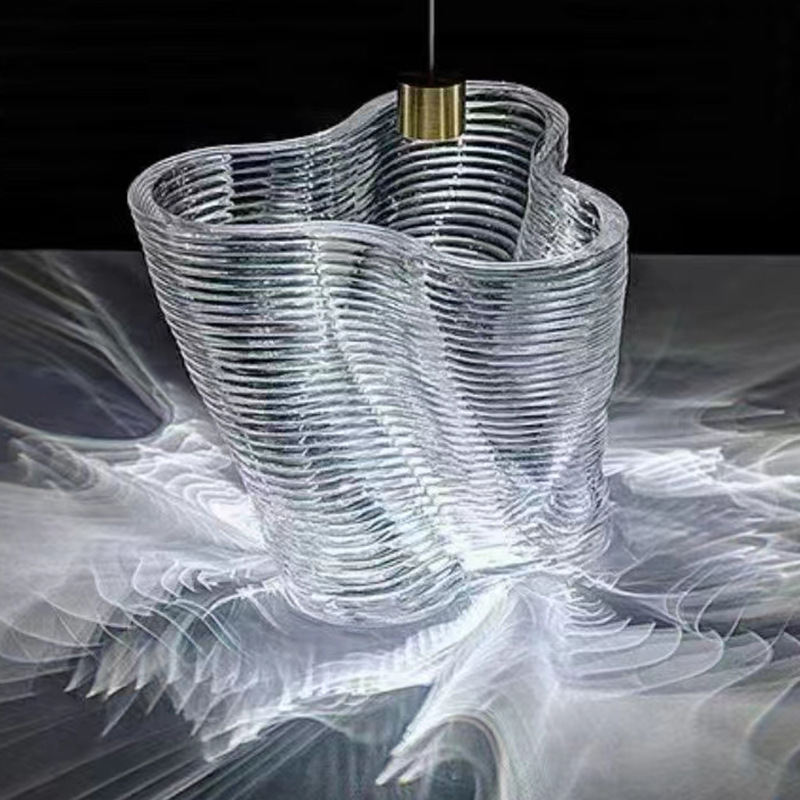

| PMMA | Signs, transparent pipes, optical lenses | PMMA has high transparency, low density, high strength, good toughness, UV resistance, and atmospheric aging resistance. |

| PTFE | Isolation and protection screens for chemical pipelines, pumps, linings, and electrical equipment | PTFE has excellent chemical corrosion resistance and is known as the "king of plastics". Good high-temperature and low-temperature resistance, low friction coefficient, and self-lubricating properties. |

| EP | Plastic molds, precision measuring tools, electronic components | EP has high strength, heat resistance, corrosion resistance, good insulation, and is easy to machine. |

Post Processing

When general customers seek cooperation in CNC precision machining, they often overlook the post-processing process.

The quality of a CNC machined custom product is largely determined by the post-processing process. These post-processing techniques are varied and commonly used, including oil spraying, screen printing, electroplating, oxidation, and oil spraying is mainly used for plastic CNC processing customization, although it can also be used for metal CNC processing customization, but there are still significant differences between them.

Metal materials have less adhesion and are prone to paint peeling, so before oil injection, metal materials are generally sandblasted. The CNC processing and customization of aluminum alloy materials uses oxidation to change color. In our company's CNC processing factory, oxidation is divided into conductive oxidation and anodic oxidation. Generally, the anodic oxidation film is thicker and therefore better in terms of insulation, while the conductive oxidation film is thinner and therefore better in terms of conductivity.

The fixed value of plastic CNC machining oil injection is much simpler. Our factory has invested a lot of financial and material resources in oil injection, and set up a dust-free workshop to ensure a more stable quality during oil injection.

Why Choose Us

1. One-Stop service to save time.

2. Factories in share to save cost.

3. Keyence, ISO9001 and ISO13485 to ensure quality.

4. Professor Team and Strong Technique to ensure delivery.