Common processes for plastic molding

In the heart of industry, precision and innovation are intertwined. Here, we're not just shaping shapes, we're shaping possibilities. Imagine a piece of raw material transformed by technology into a kaleidoscope of tools, parts and works of art. It's not magic, it's the art of injection molding.

The following are common process classifications for plastic molding:

Injection Molding: Injection molding, Insert molding, Double injection molding, Micro-foam injection molding process, Nano injection molding (NMT)

Blow Molding: Blow molding, hollow blow molding (Extrusion blow molding, Injection blow molding, Stretch blow molding)

Extrusion Molding

1.Injection Molding

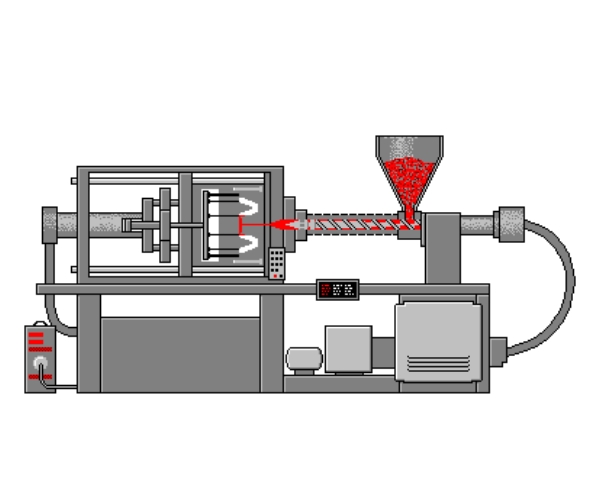

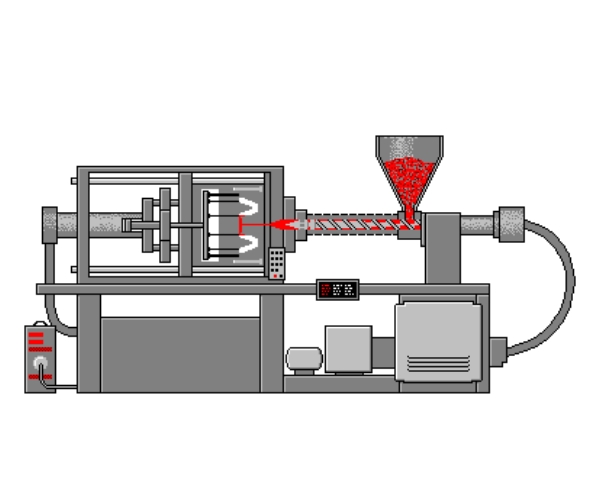

(1)Injection molding

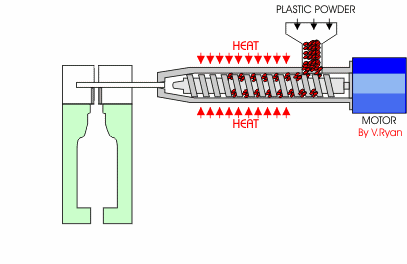

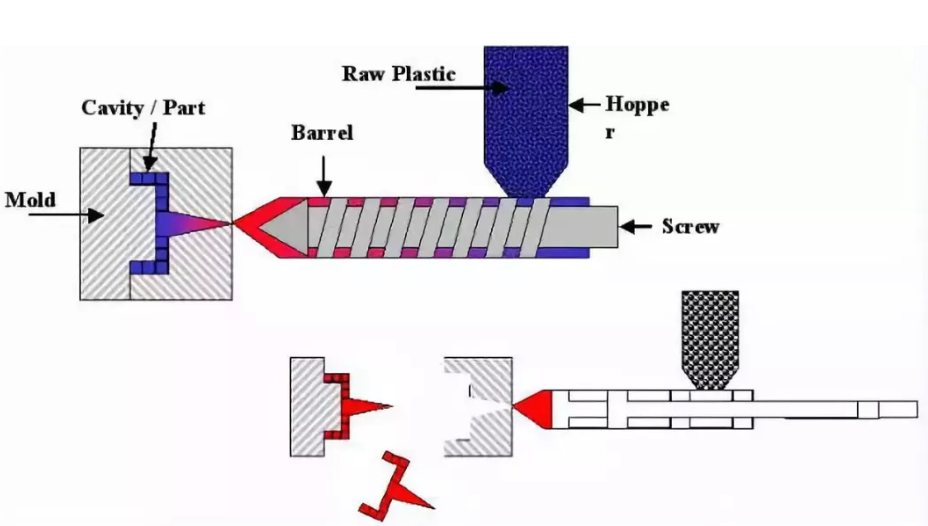

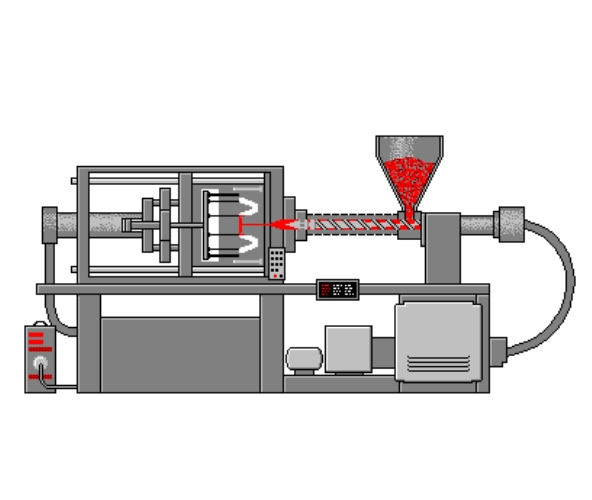

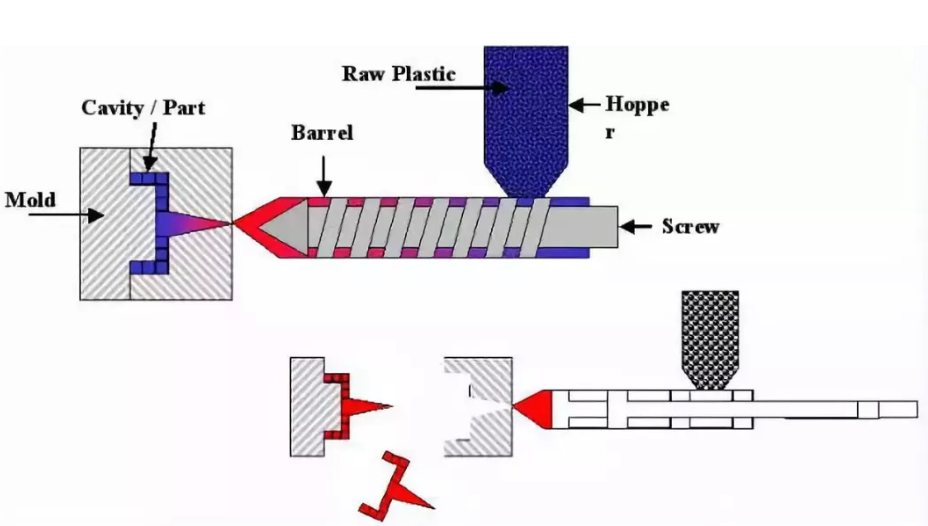

Injection molding: The principle is to add granular or powdered raw materials to the hopper of the injection machine, the raw materials are heated and melted in a flowing state, driven by the screw or piston of the injection machine, through the nozzle and the mold pouring system into the mold cavity, hardening and shaping in the mold cavity. Factors that affect the quality of injection molding: injection pressure, injection time, injection temperature.

Technics Characteristic

Advantage | defect |

| 1.Short molding cycle, high production efficiency, easy to achieve automation 2.Can form complex shape, accurate size, with metal or non-metal inserts of plastic parts 3.Product quality is stable 4.Wide range of adaptation | 1.The price of injection molding equipment is higher 2. Injection mold structure is complex 3. High production cost, long production cycle, not suitable for single small batch plastic parts production |

ApplicationIn the industrial products, the products of ABBYLEE plastic injection molding are: medical supplies, household products, kitchen supplies, the shell of electrical equipment (hair dryers, vacuum cleaners, food stirrers, etc.), toys and games, various products of the automotive industry, and parts of many other products.

(2)Insert molding

Insert molding: Insert molding refers to the injection of resin into the mold after the preprepared different material insert, the molten material and the insert joint curing, making an integrated product molding process.

Technics Characteristic

1. The pre-forming combination of multiple inserts makes the post-engineering of the product unit combination more reasonable.

2. The easy formability of resin, bending and the rigidity, strength and heat resistance of the metal can be supplemented by the combination of strong and complex metal plastic integrated products.

3. Especially the use of the combination of resin insulation and metal conductivity, the molded product can meet the basic functions of electrical products.

4. For the rigid molding products, rubber sealing gasket on the bending elastic molding products, through the matrix injection molding into an integrated product, can save the complex operation of arranging the seal ring, making the automatic combination of the post-process easier.

(3)Double injection molding

Double injection molding: refers to the molding method of injecting two kinds of plastic with different colors into the same mold. It can make the plastic appear two different colors, and can make the plastic parts show regular patterns or irregular moire patterns to improve the practicality and aesthetics of the plastic parts.

Technics Characteristic

1.The core material can use low-viscosity materials to reduce the injection pressure.

2. From the consideration of environmental protection, the core material can use recycled secondary materials.

3. According to different use characteristics, such as thick finished skin material using soft material, core material using hard material or core material can use foam plastic to reduce the weight.

4. Lower quality core materials can be used to reduce costs.

5. The skin material or core material can be used expensive and has special surface properties, such as electromagnetic wave interference, high conductivity and other materials to increase product performance.

6. The appropriate skin material and core material can reduce the residual stress of the molding product, increase the mechanical strength or product surface properties.

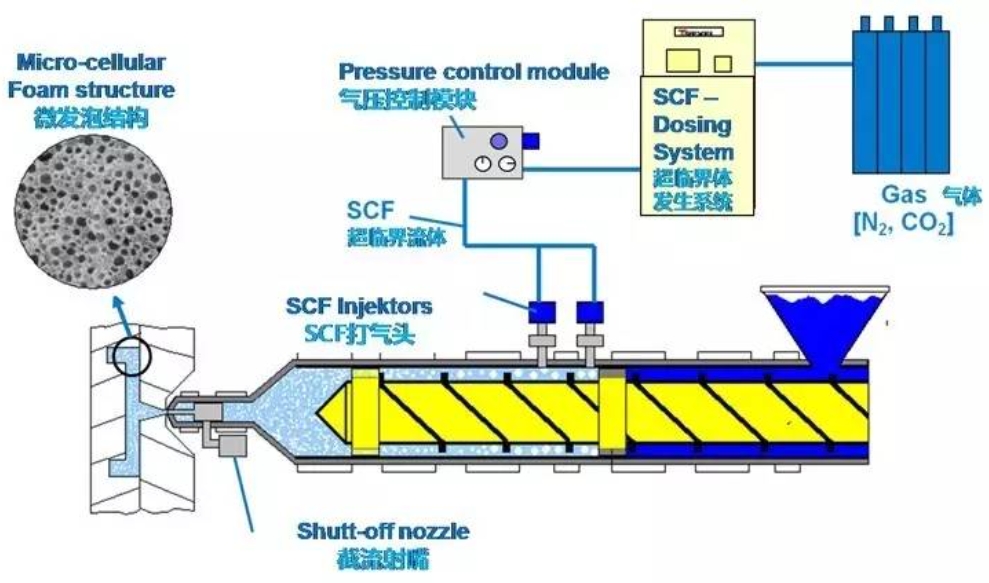

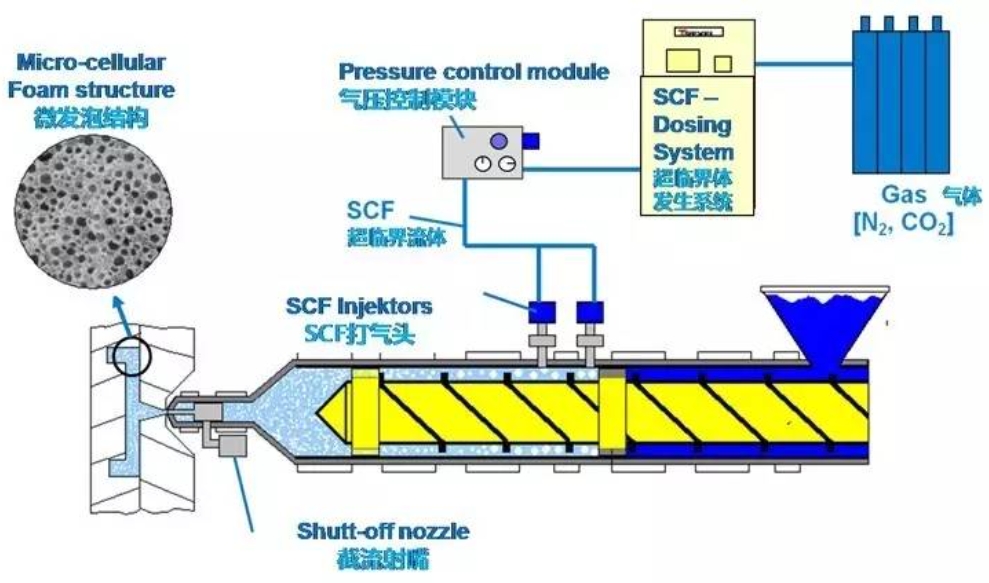

(4)Micro-foam injection molding process

Micro-foam injection molding process: is an innovative precision injection molding technology that relies on the expansion of pores to fill the product and complete the molding of the part at a low and average pressure. The microcellular foaming process can be divided into three stages: first, the supercritical fluid (carbon dioxide or nitrogen) is dissolved into the hot melt adhesive to form a single-phase solution; Then, through the switching nozzle, the mold cavity with low temperature and pressure is injected. The decrease of temperature and pressure leads to the instability of molecules, which forms a large number of bubble nuclei in the product, and these bubble nuclei gradually grow into tiny holes.

Technics Characteristic

1.precision injection molding.

2. breaking through the many limitations of traditional injection molding, can significantly reduce the weight of the parts, shorten the molding cycle.

3. greatly improve the warping deformation and dimensional stability of the parts.

Application

Car instrument panel, door panel, air conditioning duct, etc.

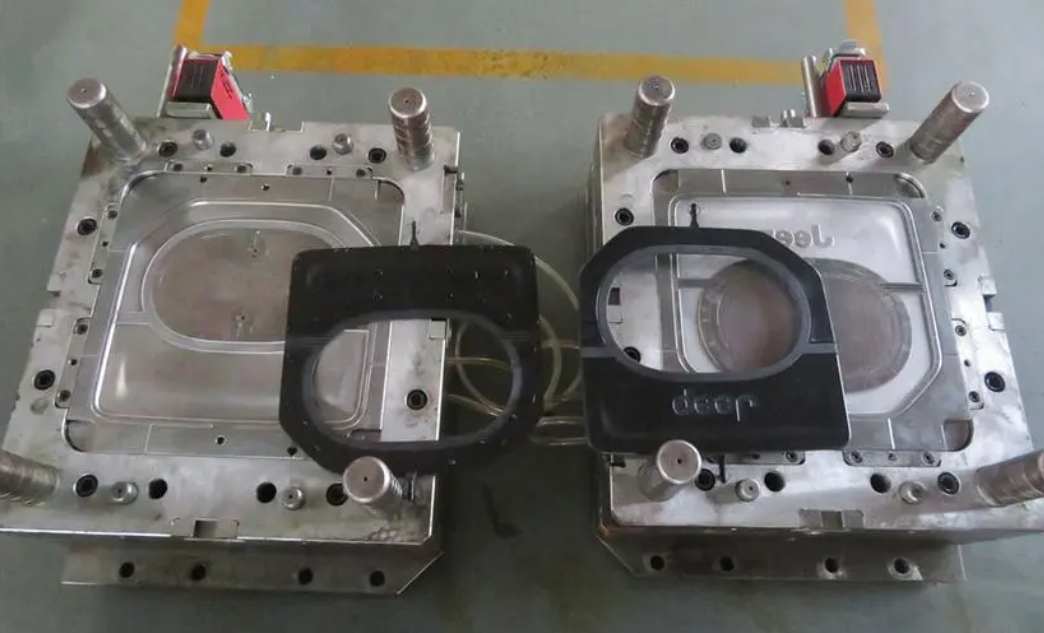

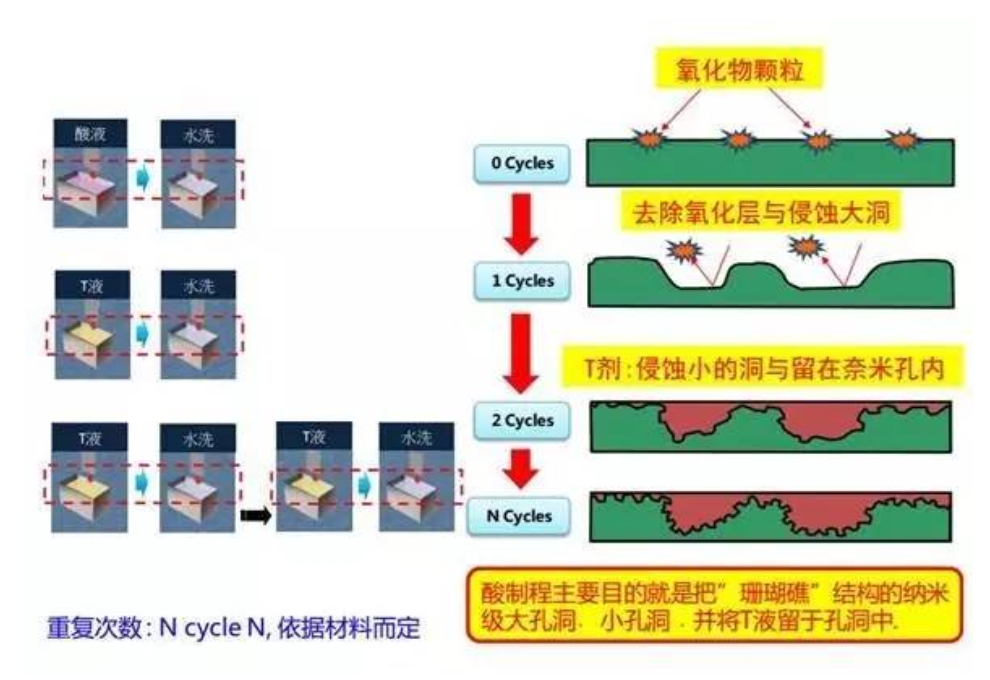

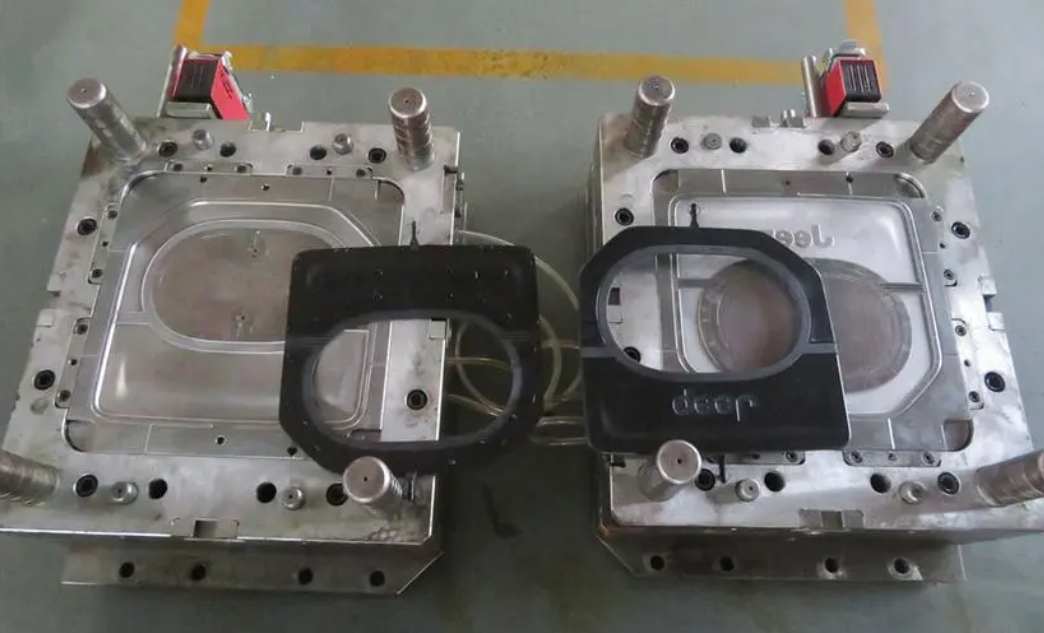

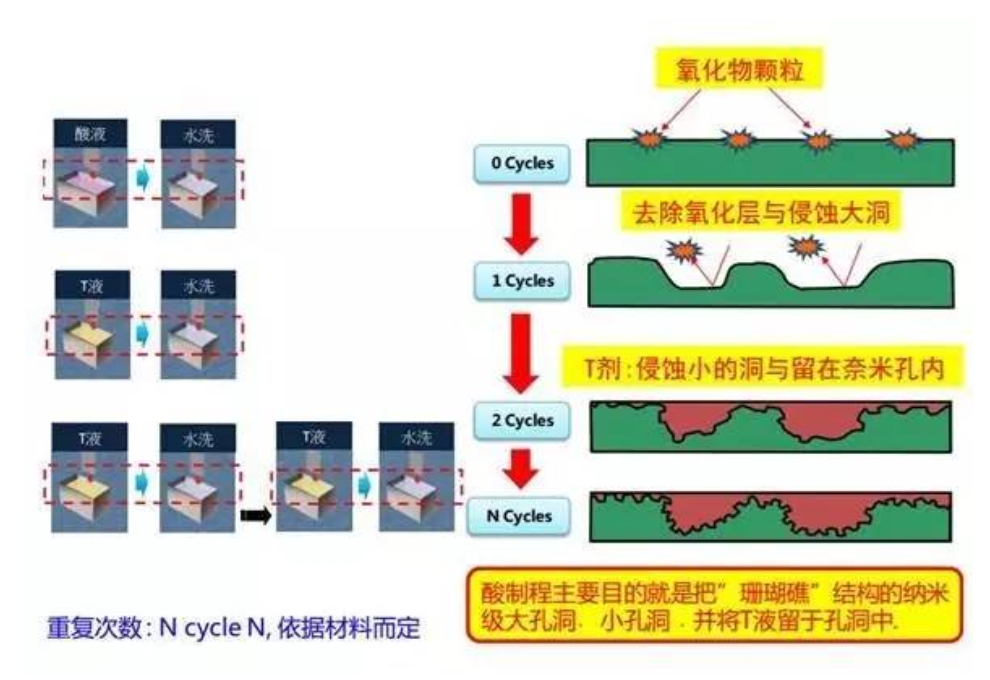

(5)Nano injection molding (NMT)

NMT(Nano Molding Technology): It is the construction method of metal and plastic combined with nanotechnology. After the metal surface is nano-treated, the plastic is directly injected into the metal surface, so that the metal and plastic can be formed as one. Nanoforming technology is divided into two types of processes according to the location of the plastic:

1.plastic for non-appearance of the integrated molding

2.plastic for the appearance of the integrated molding

Technics Characteristic

1.The product has a metal appearance texture.

2.The design of the product mechanism is simplified, making the product lighter, thinner, shorter and smaller, and more cost-effective than CNC machining method.

3.Reduce production costs and high bonding strength, and significantly reduce the use of related consumables.

Applicable metal and resin materials

1.Aluminum, magnesium, copper, stainless steel, titanium, iron, galvanized sheet, brass.

2.The adaptability of aluminum alloy is strong, including 1000 to 7000 series.

3.Resin including PPS, PBT, PA6, PA66, PPA.

4.PPS has a particularly strong bonding strength (3000N/c㎡).

Application

Mobile phone shell, laptop shell, etc.

2.Blow Molding

Blow molding: It is the method of squeezing the molten thermoplastic raw material from the extruder into the mold, and then blowing air into the raw material, the molten raw material expands under the action of air pressure, fits to the wall of the mold cavity, and finally cools and solidifies into the desired product shape.

Blow molding is divided into film blow molding and hollow blow molding two kinds:

(1)Blow molding of film

Film blow molding is to extrude the molten plastic from the circular gap of the extruder head mouth die into a cylindrical thin tube, while blowing compressed air into the thin tube cavity from the center hole of the head, blowing the thin tube into a tubular film with a larger diameter (commonly known as bubble tube), and then rolling it after cooling.

(2)hollow blow molding

Hollow blow molding is a secondary molding technology that blows the rubber-like billet closed in the mold cavity into hollow products with the help of gas pressure. It is a method to produce hollow plastic products. The manufacturing methods of hollow blow molding are different, including extrusion blow molding, injection blow molding and stretch blow molding.

1)Extrusion blow molding:Extrusion blow molding is to use the extruder to extrude the tubular billet, clip it in the mold cavity and cover the bottom while it is hot, and then blow the compressed air into the tube billet cavity.

2) Injection blow molding:The blank used is obtained by injection molding. The billet is left on the core of the mold, and after the mold is closed by blow molding, compressed air is passed through the core mold, the billet is blown, cooled, and the product is obtained after demoulding.

Advantage

The product wall thickness is uniform, the weight tolerance is small, the post-processing is less, the waste corner is small; Suitable for the production of large batch of small fine products.

3)Stretch blow molding:The billet that has been heated to the stretching temperature is placed in the blow molding mold, and the longitudinal stretch is carried out with the stretching rod, and the transverse stretch and blow is carried out with the blown compressed air, so as to obtain the method of product.

Application

1.Film blow molding is mainly used to manufacture plastic film.

2.Hollow blow molding is mainly used to make hollow plastic products (bottles, packaging barrels, watering cans, fuel tanks, cans, toys, etc.).

3.Extrusion Molding

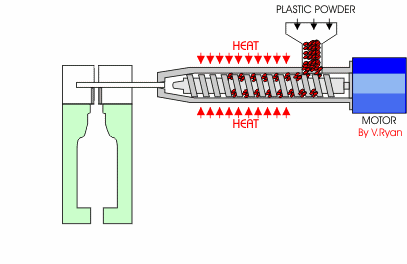

Extrusion molding: mainly suitable for thermoplastic molding, but also suitable for some of the good flow of thermosetting and reinforced plastics molding. The molding process is to use a rotating screw to heat and melt the thermoplastic raw material, extrude it from the head with the required cross-section shape, and then finalize it by the shaper, and then chill and solidify it through the cooler to become the product of the required cross-section.

Technics Characteristic

1.Low equipment cost.

2.The operation is simple, the process is easy to control, easy to achieve continuous automated production.

3.High production efficiency; The product quality is uniform and dense.

4.Products or semi-finished products of various section shapes can be formed by changing the die of the head.

Application

In the field of product design, extrusion molding has strong applicability. The types of extrusion products are pipe, film, bar, monofilament, flat tape, net, hollow container, window, door frame, plate, cable cladding, monofilament and other profiles.

Join ABBYLEE to explore the infinite wonders of injection mold processing and open a new era of creativity.