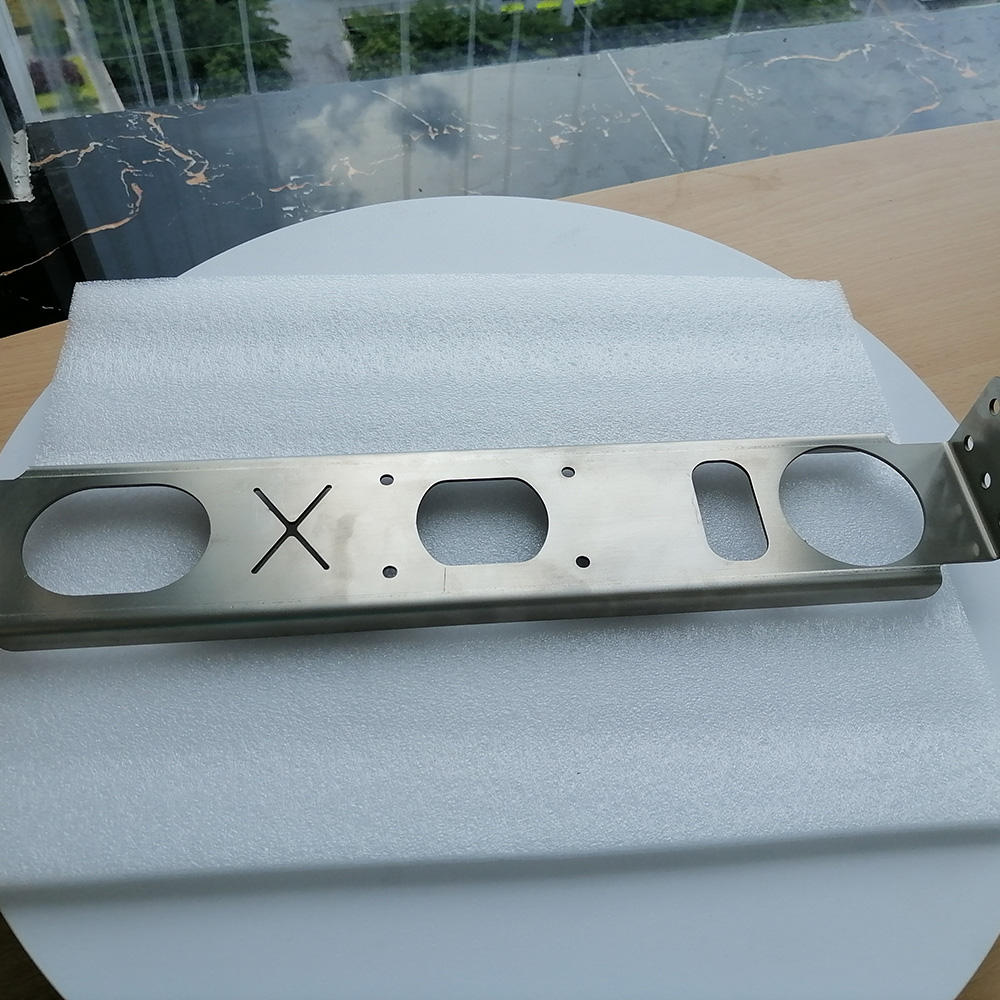

OEM laser cutting metal part Service custom

Product Detail

Laser cutting equipment is also suitable for producing small batches of parts of various sizes. Due to the transmission characteristics of laser, laser cutting machines are generally equipped with multiple CNC worktables, and the entire cutting process can be fully CNC controlled. Laser cutting uses CNC (Computer Numerical Control) to guide the laser beam to cut according to the trajectory set by the system. The focused laser beam is directed at the material, and then melts, burns, evaporates, or is blown away by the gas jet, leaving a high-quality surface and smooth edges. The surface roughness is only tens of microns. Even laser cutting can be used as the last process. No machining is required and the parts can be used directly.

Features

Application

Laser cutting metal parts have a wide range of applications in various fields. For example, laser cutting metal parts are found in aerospace, aviation, military industry, machinery, post and telecommunications, transportation, chemical industry, medical equipment, daily appliances and light industry.

Parameters

We have a variety of materials and different processing methods for you to choose from.

| Processing | laser cutting metal parts |

| Materials | Steel, Stainless Steel, Brass, Copper, bronze, Aluminum, Titanium, silicon steel, nickel plate etc |

| Processing Details | Welding, Washing and grinding, Removing burrs, Coating, etc |

| Surface Treatment | Brushing, Polishing, Anodized, Powder Coating, Plating, Silk Screen, Laser Engraving |

| Quality System Certificate | ISO 9001 and ISO 13485 |

| QC System | Full inspection for every processing. Providing inspection certificate and material. |

Surface Treatment

Quality Control Process

Packaging And Shipping