Starting your happy customized manufaturing of Plastic Injection Molding at ABBYLEE

Certification

ISO9001:2015 ISO13485 Keyence Quality First

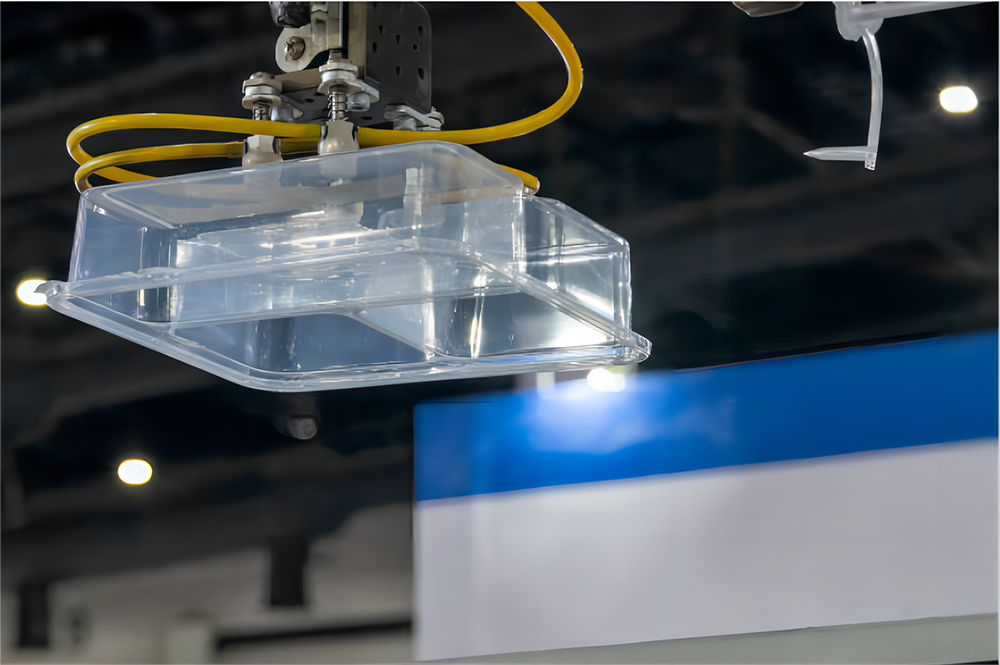

Plastic Injection Molding at ABBYLEE

Xiamen ABBYLEE Tech Co. Ltd specializes in plastic injection molding and metal fabrication. They have their own injection workshop and also partner with cross-shareholder mould making and metal fabrication manufacturers to ensure competitive pricing for their clients.

Xiamen ABBYLEE Tech Co. Ltd follows the ISO9001, ISO13485, and Keyence standards to ensure the highest standards of product quality in terms of quality and tolerance.

Why choose ABBYLEE to make Plastic Injection Molding ?

1.ABBYLEE has its own injection factory and the cross shareholder of mould making toolings and metal fabrication . This allows them to offer the most competitive prices in the market.

2.ABBYLEE is certified with ISO9001:2015 and ISO13485, ensuring that their manufacturing processes meet international quality standards. They also have a Keyence and Double Checking Team, including both factory and ABBYLEE QC team, to control and maintain the quality of their products.

3.With over 10 years of experience and more than 3000 completed projects, ABBYLEE has a strong track record in the industry. They have a team of experts, engineers, production managers, project managers, and QC controllers who are dedicated to following orders and ensuring fast delivery.

4.ABBYLEE is known for providing a 5-star service experience. They offer a 12-hour quoting time, and their professional engineer sales team is available to assist with any design issues or questions.

5. ABBYLEE has branches in the US and Australia, which helps to overcome any concerns related to time difference, language barriers, and trust issues. This ensures a smooth communication and customer experience, especially for new customers placing their first order.

How to define texture ,common polishing, and glossy polishing for the injection molding

In injection molding, texture, common polishing, and glossy polishing refer to different types of surface finishes that can be achieved on the molded plastic parts. Here are their definitions:

Texture: Texture refers to the surface patterns or designs intentionally added to the mold cavity to give the final product a specific texture or feel. This can include patterns such as wood grain, leather, or other desired textures. Texture enhances the aesthetics and tactile experience of the product. At ABBYLEE,we have the texture book for your to decide the texture code.

Common polishing: Common polishing, also known as standard polishing, is a surface finish that results in a smooth and glossy appearance. It involves using abrasive materials and techniques to remove imperfections and create a uniform and reflective surface on the molded part. Common polishing is widely used for products where a high-gloss, sleek appearance is desired, such as electronic devices or consumer goods.