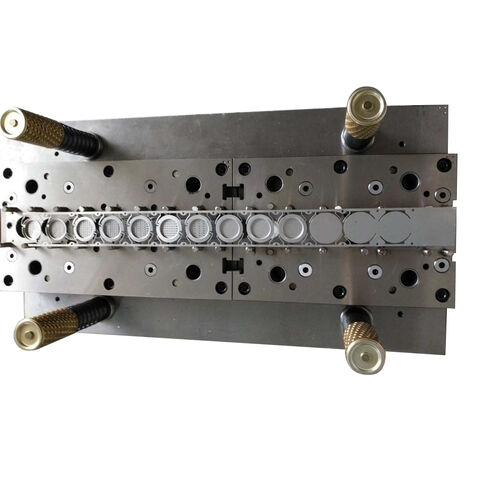

Stamping Mold Professional Factory Custom High precision Industrial Metal China Punching Mold Stamping Die

Product Detail

The manufacturing process of stamping molds requires professional technology and experience. ABBYLEE communicates with clients to understand product requirements and needs, including product shape, size, materials, etc. According to product requirements and stamping process, design the structure and components of the mold, including punches, die bases, guide pillars, etc. Use CNC machine tools to process mold parts, including milling, turning, grinding and other processes. Assemble the processed mold parts, and conduct mold debugging and trial testing to ensure that the mold can meet product requirements. Based on the product inspection results, mold corrections and improvements are made to improve mold performance and product quality.

Features

Application

Stamping Mould Tooling can produce many parts for use in various fields.. For example, stamping processing is found in aerospace, aviation, military industry, machinery, post and telecommunications, transportation, chemical industry, medical equipment, daily appliances and light industry.

Parameters

We have a variety of materials and different processing methods for you to choose from.

| Product Name | Custom Stamping Mould Tooling |

| Materials | SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc. |

| Mould Type | Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer’s requirements |

| Mould Life | 250000-300000shots |

| Quality System Certificate | ISO 9001 and ISO 13485 |

Production Flow

Quality Control Process

Packaging And Shipping